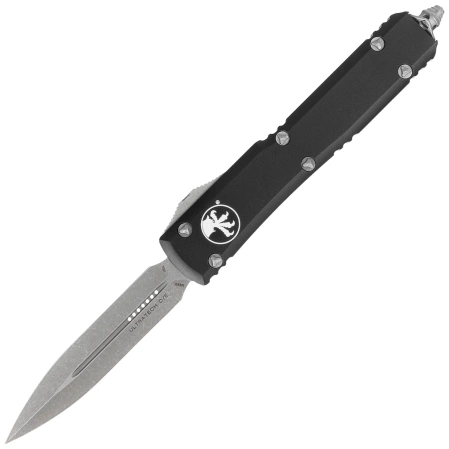

- Ultratech D/E Black Aluminum, Apocalyptic full-sized OTF automatic knife from Ultratech series. Operating in D/A mode, it features a lightning-fast blade deployment mechanism. Handle black anodized aluminum. Designed by Tony Marfione, owner of Microtech.

439,54 €

439,54 €This product is intended for use only by adults with knowledge and experience in handling sharp cutting tools. Improper use of the knife can result in serious injuries. The blade is extremely sharp and can easily cut through skin and tissue; therefore, extra caution should always be exercised while cutting, and hands should be kept away from the cutting edge. To prevent the knife from slipping, it is recommended to cut on a stable, non-slip surface and avoid excessive force, which may cause uncontrolled blade movement.

Leaving the knife on the edge of a table, countertop, or in easily accessible places—especially where children are present—poses a significant safety risk. The knife should always be properly secured after use, ideally by placing it on a stable surface or storing it in designated knife blocks, protective sheaths, or magnetic strips. The knife should never be used for tasks it is not designed for, such as opening cans or prying objects, as this can damage the tool and lead to dangerous accidents.

A dull blade increases the risk of injury, as it requires more force and is more likely to slip from the material being cut. Therefore, it is essential to sharpen the knife regularly to maintain optimal sharpness. Additionally, proper cleaning and drying of the knife are necessary to prevent corrosion and bacterial growth. Periodic inspection of the handle and blade is recommended to check for cracks, chips, or looseness. If any damage is detected, the knife should be repaired or replaced immediately.

When using the knife, focus solely on the task at hand—avoid talking on the phone, watching television, or other distractions while cutting. Ensure proper lighting in the workspace for better visibility and control. Please note that some countries or regions have laws restricting the ownership and carrying of knives. Before purchasing or using this knife, verify that its use is legal in your location according to applicable regulations.

Following these safety guidelines will help ensure safe and effective knife use, minimizing the risk of accidents and extending the lifespan of the tool.

Ultratech D/E Black Aluminum, Apocalyptic is a full-size OTF (Out The Front) automatic knife from the Ultratech series. Equipped with a hell of a fast mechanism that extends a razor-sharp blade. 100% made and assembled in the USA. Designed by Anthony Marfione, knifemaker and owner of Microtech Knives.

Ultratech OTF Line - Microtech's flagship model in the OTF line, which set the standard for all Out The Front knives. Ultratech's proprietary trigger spring design, which remains in the “resting” position at all times, except when used. This prevents the spring from fatigue, reducing wear and tear on the internal trigger mechanisms which ensures that the knife will always function effectively. The light weight, the ability to open and close with one hand, the slim shape of the handle and the sharp blade make it a one-of-a-kind knife, available only from Microtech.

M390 Microclean® - a martensitic high-performance chrome steel produced by powder metallurgy. Due to its alloy concept, it has extremely high wear resistance and high corrosion resistance. Due to its high wear resistance, it adequately maintains the shape of the edge, so the blade stays sharp for a very long time (requiring minimal maintenance). Another of the advantages is resistance to the formation of "wire" during sharpening. The steel has a high chromium content of 20.0% (Cr) doped with 1.9% carbon (C), vanadium 4.0% (V), and is hardened between 59-61 HRC. This super steel is comparable to Carpenter's CPM 20CV or CTS-204P steels. Manufactured by Böhler Edelstahl in Kapfenberg, Austria.

Blade - machine-ground in a Dagger D/E (Double Edge) style, sharpened on both sides. Effectively aged with an Apocalyptic finish. The blade was brought out with a high flat grind, providing excellent cutting properties. As a result, the knife has excellent piercing properties while maintaining its strength. The strong mechanism of extending / retracting the blade with the help of a moled Thumb Slide, a stepped slide under the thumb, requires for safety the application of a specific force to overcome the resistance of the spring. The method of opening provides seamless opening for both right and left-handed people.

Handle - made with excellent precision in 3D technology on CNC milling machines, from black anodized 6061-T6 aluminium. The surface texture of the Handle makes the knife non-slip in the hand during use. There are notches (jimping) on the back and bottom of the handle for a more secure grip. The slim profile and milled two-position (right/left) solid deep-carry clip allow the knife to be carried discreetly in the pocket, in tip-down (blade tip down) position. The clip bears the Microtech logo, serial number and production date. The Handle is finished with a glass breaker, a solid steel triangle, into which a tungsten carbide ball has been pressed. It also features a hole for interweaving a decorative cord.

Technical data:

Product number: 122-10 AP

Product name: Ultratech® D/E Black Aluminum, Apocalyptic® Standard

Overall length: 216.0 mm / 8.5"

Blade length: 87.4 mm / 3.44"

Blade thickness: 3.3 mm / 0.13"

Handle length: 117.0 mm / 4.625"

Handle thickness: 11.9 mm / 0.47"

Weight: 102.0 g / 3.60 oz

Blade material: Böhler M390

Blade hardness: n.d.

Blade grind: Flat

Blade finish: Apocalyptic

Handle material: 6061-T6 Aluminum

Handle finish color: Black

Backspacer material: 6061-T6 Aluminum

Backspacer color: Black

Clip: Right/left, Tip-down

Clip material: Stainless Steel

Pivot mechanism: n.d.

Locking mechanism: Slide Lock

Opening method: Automatic, push/pull Thumb slider

Additional accessories: none

Designer: Tony Marfione

Brand: Microtech Knives

Manufacturer: Microtech Knives

Country of origin: USA

Developed by: the Sharg® company